CNC PRESS BRAKE BENDING SERVICE

V-grooving is a precise metal processing technique used to create sharp bends or folds by cutting a V-shaped groove along the bend line of a metal sheet. The groove reduces the material thickness at the bend point, allowing for a cleaner, sharper, and more accurate fold, especially on thicker or rigid materials.

Purpose of V-Grooving:

-

Achieves tight internal bend radii that can’t be done with regular press brake bending.

-

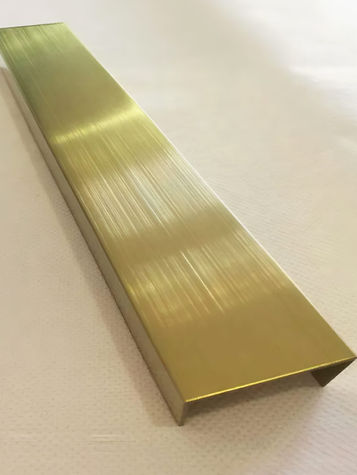

Enhances the aesthetic quality of architectural or decorative metalwork by producing crisp, sharp corners.

-

Allows bending thick sheets without distortion or cracking.

-

Reduces spring-back during bending, improving accuracy.

Common Applications

Materials Suitable

Benefits

-

Architectural panels & facades (e.g., elevator panels, column covers)

-

Furniture with sharp bends and modern finishes

-

Signage and decorative trims

-

Custom enclosures or casings for electronics

-

Kitchen equipment, especially when using stainless steel

How It Works:

1. A V-shaped groove is cut into the back side of the metal sheet using a CNC V-grooving machine.

2. The depth is carefully controlled, leaving a thin layer (typically 0.3–0.8 mm) uncut.

3. The sheet is then bent along the groove using a press brake or manual bending.

4. The result is a sharply defined outside corner with a minimal bend radius.

-

Stainless Steel (SS)

-

Aluminum (AL)

-

Mild Steel (MS)

-

Galvanized iron (GI)

-

High precision and clean edge appearance

-

Allows for complex folding without welding

-

Time-saving in post-processing (less grinding or polishing)

-

Enhances the luxury/modern look of metal products